Overhead Cranes

Overhead Bridge Cranes

Kristian Electric is proud to be one of Canada’s trusted providers for overhead bridge cranes since 1964. Whether you’re moving heavy loads in a warehouse or just looking for a small material handling solution for the shipping bay, our team can find a custom-built crane solution that will streamline your unique industrial lifting application.

As one of Alberta and Saskatchewan’s trusted leaders in overhead cranes, we provide a full range of lifting systems, from single and double girder cranes to custom-engineered solutions.

When you partner with Kristian Electric, we take the hassle out of buying a crane. From day one, our team is focused on delivering exactly what you need—quickly, efficiently, and within your timeline. With our expert team and decades of knowledge, we’re ready to build, ship, and install your next crane. Let us show you how easy it can be.

Why Choose Our

Overhead Bridge Cranes?

With more than 60 years of experience serving industries across Canada, our overhead bridge crane systems are engineered to the highest standards, ensuring your facility can handle heavy lifting with ease. By offering both standard and custom bridge crane configurations, we cater to industries ranging from automotive and manufacturing to steel and paper production.

- Single Girder Overhead Cranes: Ideal for light to moderate loads, these cranes offer cost-effective, reliable solutions for your lifting needs.

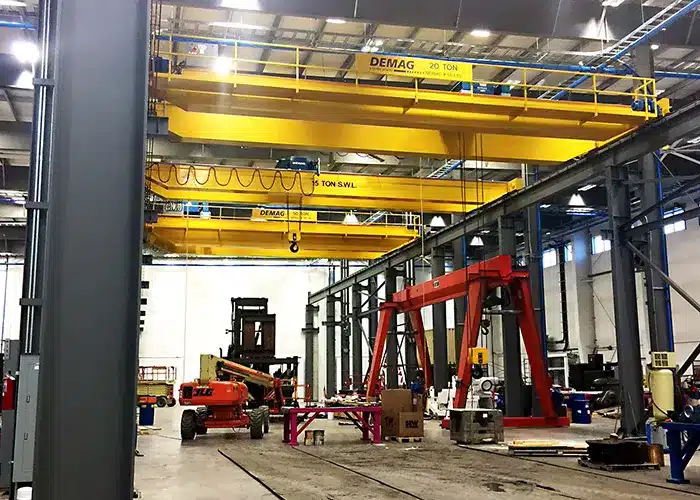

- Double Girder Overhead Cranes: Designed for heavy-duty applications, double girder systems provide increased capacity and better hook height, making them suitable for more demanding tasks.

- Box Girder Overhead Cranes: For larger capacities and longer spans, custom-built girders provide superior strength and durability, making them ideal for handling heavier loads, typically 20 tons and above, with crane spans extending up to 120 feet.

- Custom Solutions: We offer tailored crane systems built to your specifications, ensuring that your unique requirements are met with precision.

Our cranes are manufactured in accordance with CMAA (Crane Manufacturers Association of America) specifications and all applicable Canadian safety regulations.

Overhead Crane Configurations

Our overhead crane offerings are designed with flexibility in mind, ensuring that each system meets your specific lifting and operational requirements. Depending on your facility’s layout and lifting needs, we offer:

- Top Running Cranes: These cranes run on rails mounted on top of runway beams, offering the maximum hook height. They are ideal for handling large loads and are used in industries such as aerospace, automotive, and steel production.

- Under Running Cranes: Mounted beneath the runway beams, these cranes are a great choice when headroom is limited. Under running cranes are versatile and provide optimal coverage in tighter spaces.

Both single girder and double girder cranes are available in these configurations, allowing us to provide solutions for a wide range of capacities and spans. Whether you’re looking for a light-duty single girder crane or a heavy-duty double girder crane, we can design and install the perfect system for your needs.

Overhead Crane Benefits

Our overhead bridge cranes offer significant advantages over traditional material handling methods, including:

- Increased Efficiency: Moving large loads with a bridge crane reduces labor time and improves workflow in industrial settings.

- Improved Safety: Our cranes are designed with integrated safety features that minimize the risk of workplace injuries, ensuring the safe movement of materials across your facility.

- Maximized Space: Overhead bridge cranes are ideal for maximizing floor space, as they allow for lifting and transporting materials above ground level without the need for additional floor-based equipment.

Whether you need a crane system for infrequent use or continuous, heavy-duty operations, our experts can recommend the best solution to meet your load and duty requirements.

Custom Solutions for Canadian Industries

As a leading provider of overhead crane solutions across Canada, we offer systems tailored to industries ranging from manufacturing and steel production to energy and logistics. Our team works closely with you to understand your facility’s needs and develop a custom bridge crane solution that optimizes your operational efficiency.

For businesses that need more than a standard crane setup, our team can design fully customized systems, including:

- Runway extensions for increased crane reach

- Free-standing bridge cranes for flexibility in installation

- Turnkey installation and maintenance services to ensure seamless integration

Contact Us for Your Overhead Crane Needs

Ready to enhance your facility’s lifting capacity? Contact Kristian Electric today to learn more about our overhead bridge crane solutions in Canada. Whether you’re looking for a single girder crane or a custom-engineered bridge crane, our team is here to help. Contact us for a quote today!